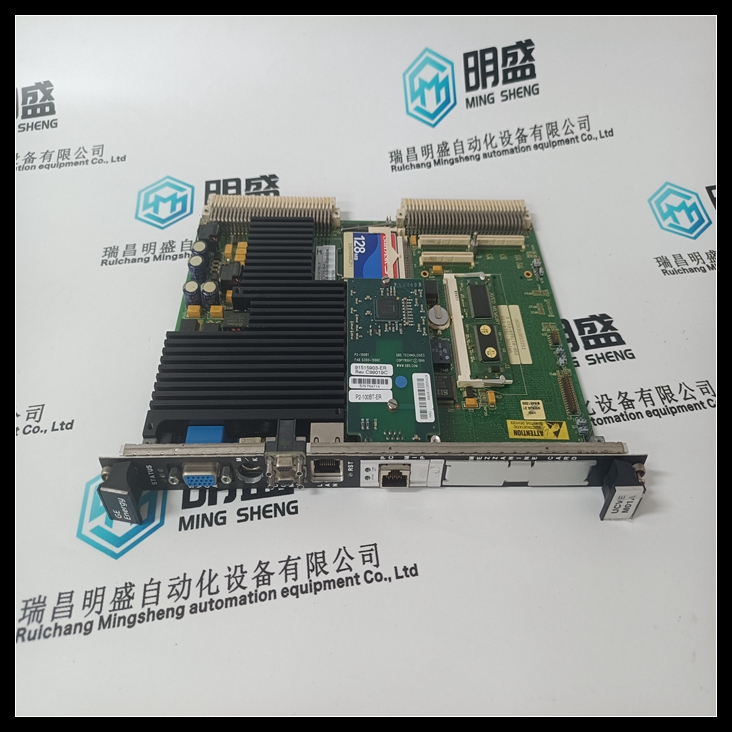

VMIVME-7614-133工控处理器模块库存

类目:GE

型号:VMIVME-7614-133

全国服务热线:+86 15270269218

手机:+86 15270269218

微信:+86 15270269218

QQ:3136378118

Email:stodcdcs@gmail.com