MVME2305-900逻辑模拟量顺序模块

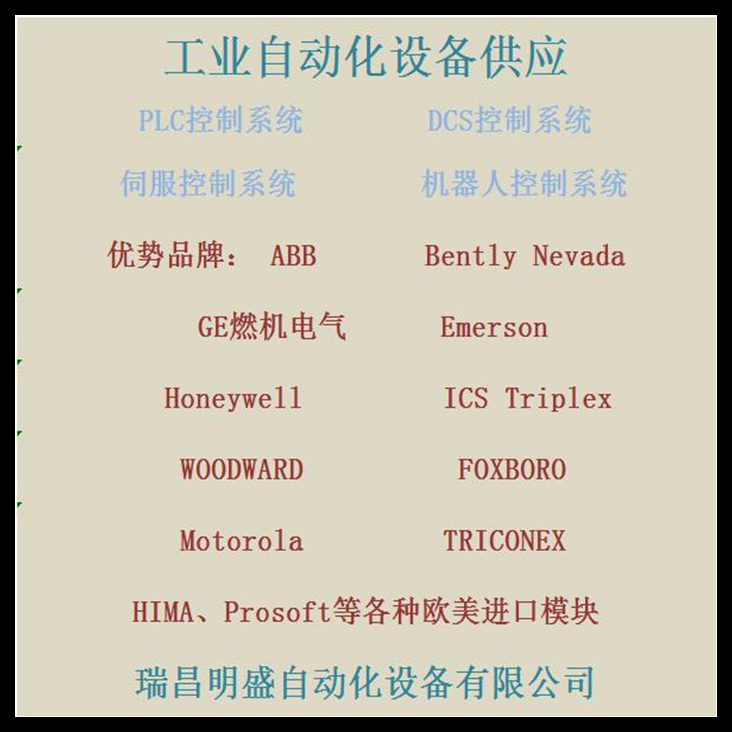

类目:MOTOROLA

型号:MVME2305-900

全国服务热线:+86 15270269218

手机:+86 15270269218

微信:+86 15270269218

QQ:3136378118

Email:stodcdcs@gmail.com